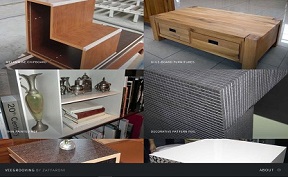

On-line portfolio of solutions obtained through "Miter-Folding" technology

The milling-glueing-folding-pressing line consists of longitudinal precision milling machines for panels, with two or more heads, belt or roller conveyor system with guides for the pieces and lower contrasts, with processing capacity in widths of 65, 92, 130 and 160 cm.

It is a plant that boasts the presence of high-productivity modules, used for the production of medium and large quantities of profiles for door frames, frames, wall units and other details assembled with the "Miter-Folding" system.

The "FML" are machines designed for multiple grooving of continuous "V" and other shapes on chipboard panels already trimmed to size, coated with PVC, various laminates , wooden plates, plastic laminates, etc...

The entire operating logic is controlled by a multi-axis numerical control with a continuous path of the CNI type with integrated PLC. The programming takes place in a simplified way, by entering the dimensions of the piece, with visualization of the functions on video, dimensions and type of grooves.

The heads of the tools installed on the work carriage are equipped with automatic vertical release and automatic return to the work start point, which can be of the following types: "2c" for 90-degree "V" cuts, with two circular blades. "2cr" for "V" cuts with adjustable angle from 30 to 90 degrees, with two circular blades; "t" to cut or mill.

The company "ZAFFARONI" (Turate - Como - Italy) is always ready to offer solutions for precise "V" groove milling for wood-based elements.