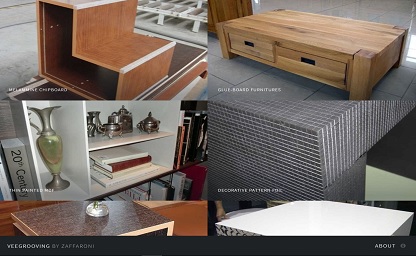

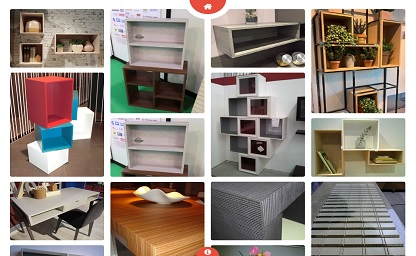

Sectors of application

We find this assembly technology applied to the production of frames for furniture, drawers, tables, frames for doors for interiors, photo frames, jambs and profiles in general, speakers for sound diffusion, hanging furniture for living rooms, bedside tables, wall shelves, components for wardrobes.